Mar. 31, 2023

Mechanical Parts & Fabrication Services

Induction Pipe Bending is a type of metal forming that bends tubes by localized heating using a high or medium frequency induction power supply. Therefore, Induction Pipe Bending Machine is a kind of metal forming equipment, not only suitable for round pipes/tubes, but also for rectangular/square pipes and I-beams .

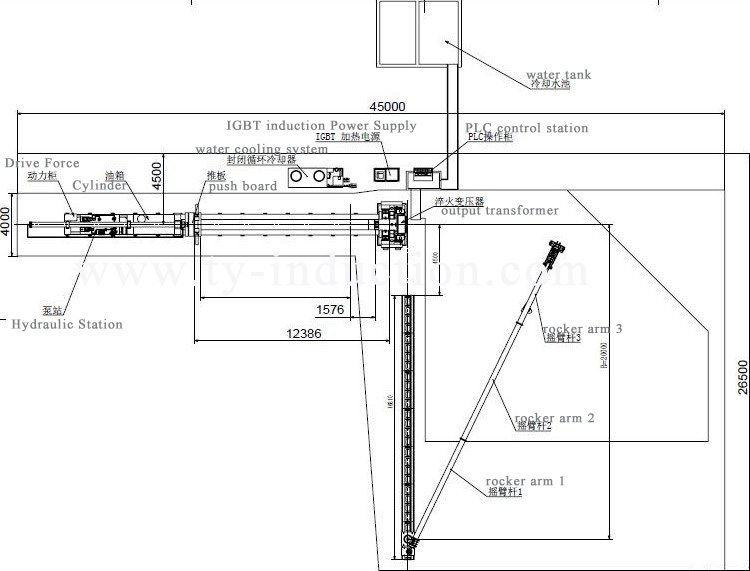

Item 1. Induction Power supply (IGBT technology based)

Item 2. Output Transformer

Item 3. Inductor & shower

Item 4. Closed Water Cooling System: to supply cooled water to Induction Power Supply and Inductor

Item 5. Hydraulic Bending Machine (to make pipe bent)

5.1 Hydraulic System: Hydraulic Cylinder, Pump Station, Oil Tank

5.2 Mechanical System

Item 6. Infrared Temperature Thermometer: to detect temperature and feedback to Central Control Station

Item 7. Central Control station (Siemens PLC & Touch Panel)

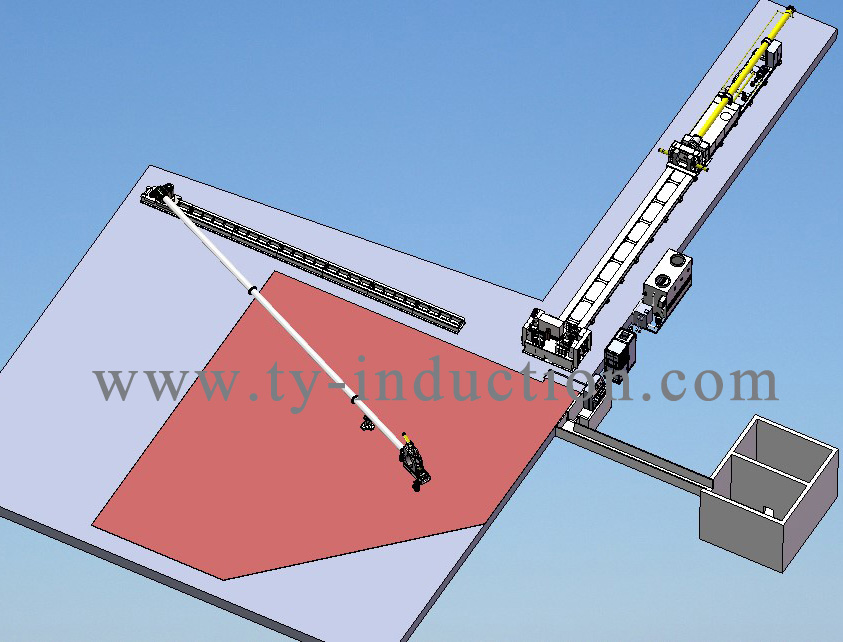

See the example drawings below for your reference!

A length of straight pipe is passed through the induction bender and the leading end of the pipe is clamped on the pivot arm. The machine uses induction coils to heat a narrow band of pipe. The pipe is pushed by hydraulic cylinder through the machine, it creates a bend with the desired radius. The heated material just after leaving the induction coil is quenched by water showers on the outer surface of the pipe. Due to the unheated pipe on both sides, the thermal expansion of the narrow-heated part of the tube is restricted, which causes the diameter shrinkage when cooled.

The induction bending process minimizes the problem of inner wall thickening and outer wall thinning by precisely controlling the bending temperature, the speed at which the pipe is pushed through the induction coil, the position of the induction coils relative to the pipe (closer to the inner or outer arc), and other factors.

The bending angle of induction bending ranges from 0° to 180° etc., or a specific bending angle can be customized. The bend radius is specified as a function of diameter. Induction elbows are available in bend radii ranging from 2.5D to 40D, where D is the nominal pipe diameter.

Featured content:

ㆍCan bend different shape pipe & beam: Square & Rectangle and I & L-Beams

ㆍCan bend pipes and beams in different material: Carbon & Alloy steel, Stainless steel

ㆍCan bend different type of pipes: Seamless pipe & Welded pipe

ㆍBending Radius and Angle can be adjusted within certain range

ㆍPipe heated uniformly by Induction Machine brings Good Quality of bent pipe: very less Distortion, very less Wall Reduction and good Ovality

ㆍPipe heated fast by Induction Machine brings High Efficiency, Low operating cost and Low Energy Consumption

ㆍCan be operated Automatically & Manually

ㆍWhole machine is controlled by PLC with Touch Panel

ㆍInfrared Thermometer controls heating temperature and can Record

ㆍCost efficiency, straight material is less costly than standard components (e.g. elbows) and bends can be produced faster than standard components can be welded.

ㆍInduction bending is a clean process. No lubrication is needed for the process and water needed for the cooling is recycled.

induction pipe bending machine

Previous: High Head Slurry Pump: A Reliable Solution for Efficient Handling of Abrasive Slurries

Next: Importance of Solid Control Equipment in Drilling Operations

Related Articles

If you are interested in sending in a Guest Blogger Submission,welcome to write for us!

All Comments ( 0 )